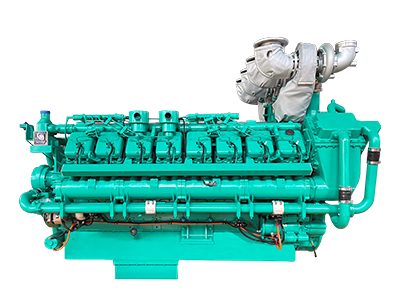

Diesel Engine

Generator Set

During the long-term operation of diesel engines,due to incomplete fuel combustion,evaporation and residue of lubricating oil,and the mixture of impurities in the intake air,carbon deposits are prone to form in parts such as the combustion chamber,intake passage,fuel injectors,top of the piston,and valves.Excessive carbon deposits can lead to problems such as engine knocking,difficult starting,reduced power,and increased fuel consumption.Regular cleaning of carbon deposits helps maintain the stable operation of the engine.

The methods for cleaning carbon deposits in diesel engines can be divided into two categories:non-disassembly cleaning and disassembly cleaning.Non-disassembly cleaning is suitable for situations where the degree of carbon deposit is relatively mild,with a short operation cycle and no damage to the structure.Common methods include adding carbon deposit cleaning agents,which are injected through the oil passage or intake port,allowing them to enter the combustion chamber along with the fuel oil.During operation,they soften and remove carbon deposits.Another approach is to use an engine cleaning device that does not require disassembly.By atomizing the cleaning solution,the carbon layer on the surface of the intake system and the combustion chamber is gradually dissolved.

When the carbon deposit is heavy or a hard coking layer is formed,disassembly and cleaning methods should be adopted for treatment.It mainly involves disassembling components such as fuel injectors,intake manifolds,and valves,and removing deposited carbon blocks through ultrasonic cleaning,chemical immersion,or manual brushing.When carbon deposits in the combustion chamber are severe,techniques such as scraping off the top of the piston and mirror surface treatment of the cylinder can be adopted to ensure the surface smoothness.

To reduce the frequency of carbon deposit formation,it is recommended to choose low-ash diesel with stable quality,regularly change the engine oil and oil filter,and ensure good sealing of the fuel system.The air filter of the intake system should be inspected regularly to prevent impurities from entering.Long-term low-load operation of the engine is also prone to carbon deposits.Reasonably maintaining the engine's operating temperature and load level is conducive to the self-cleaning of carbon deposits.

The carbon deposit cleaning cycle varies depending on the usage conditions.For urban conditions,it is recommended to check every 10,000 to 15,000 kilometers.For high-intensity operation scenarios,the cycle can be appropriately shortened.When cleaning,dedicated equipment and compliant chemicals should be selected to avoid damage to the seals and fuel injection systems.

Carbon deposit treatment is one of the preventive maintenance links.Reasonable cleaning methods and cycle arrangements can effectively extend the service life of the engine and ensure the operational efficiency of the equipment.